MTP (Mechanical Transfer Push-on) connector structure is an improved version of MPO (Multi-fiber push-on) connector. The MTP connector has elliptical guide pins of noncorrosive steel for accurate location of fibers of the two commutating connectors and reduction of wear. Also the  MT-ferrule has a floating structure that provides integrity of physical contact of the connectors under load.

MT-ferrule has a floating structure that provides integrity of physical contact of the connectors under load.

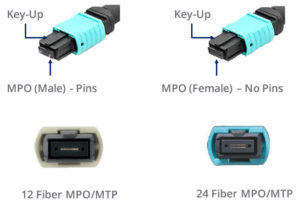

MPO is the abbreviation of multi-fiber Push On. The American standard is EIA/ tia-604-5, commonly known as FOCIS 5 High precision, precise MT guide needle and guide hole ensure the accuracy of optical fiber alignment High density, able to support 12-96 core fiber connections spare parts design. The spare parts of MTP are protected by patent.

The positive and negative of MTP connector can be changed flexibly even in the field after assembly.The guide pin of the MTP connector is stainless steel ellipse type. This design can improve the alignment accuracy and reduce the wear of the guide hole.MTP fiber optic connectors are designed with metal pins to hold the push ring in place. The guide pin can be prevented from losing MTP fiber optic connector spring design maximizes the band gap of 12-core and multi-core ribbon applications to prevent fiber damage.

From the outside there is very little noticeable difference between MPO and MTP connectors. In fact, they are completely compatible and inter-mateable. For example, an MTP trunk cable can plug into an MPO outlet and vice versa.

The main difference is in relation to its optical and mechanical performance. MTP is a registered trademark and design of US Connec and provides some advantages over a generic MPO connector. Since MPO / MTP optic fiber alignment is critical to ensure a precise connection there are some benefits in utilizing the MTP connector.

The MTP connector is a high performance MPO connector with multiple engineered product enhancements to improve optical and mechanical performance when compared to generic MPO connectors.

The MTP optic fiber connector has floating internal ferrule which allows two mated ferrules to maintain contact while under load. In addition,The MTP connector spring design maximizes ribbon clearance for twelve fiber and multi fiber ribbon applications to prevent fiber damage. Overall it provides a more reliable and precise connection.